Mushroom cultivation in India is growing step by step as an alternative supply of profits for many people. Worldwide, the US, China, Italy and the Netherlands are the top producers of mushrooms. In India, Uttar Pradesh is the leading producer of mushrooms followed by Tripura and Kerala.

What is Mushroom farming?

Mushrooms are the fruiting frame of a fungus, simply as apples are the fruiting bodies of an apple tree. A mushroom is a sort of fungus that has the Latin name Agaricus bisporus. Mushrooms belonging to fungi species is a nutritious vegetarian delicacy and a good source of high-quality protein (20-35 per cent dry weight). Presently 3 varieties of mushroom are cultivated namely, white mushroom (Agaricus bisporus), the paddy-straw mushroom (Volvariella volvacea) and oyster mushroom (Pleurotus Sajor-Caju).

No.1 Mushroom Farming Business Training Program

Learn to start your own Mushroom farm and earn up to ₹100000 per month, from your home.

In the vegetable kingdom, mushrooms are ranked with heterotrophic organisms (lower plants). Unlike high, green plants, these heterotrophs aren’t able to photosynthesis. Fungi are the scavengers of nature. In mushroom cultivation, waste merchandise consisting of chicken manure, horse manure, straw, gypsum and wastewater (from their very own compost) are used to provide the high high-satisfactory substrate from which mushrooms will grow. The ammonia is eliminated from the process air through an ammonia washer before it is returned to nature. Even ammonia from the air is used as a source of nitrogen in composting.

The fungus, also referred to as mycelium, makes use of manure as a source of energy for its combustion, liberating energy that is used for growth. Mushrooms contain many vitamins and minerals, like B- Complex and iron, and are a good source of quality proteins like lysine. Mushrooms are completely fat (cholesterol) free and also rich in antioxidants.

Different kinds of Mushroom cultivation in India:

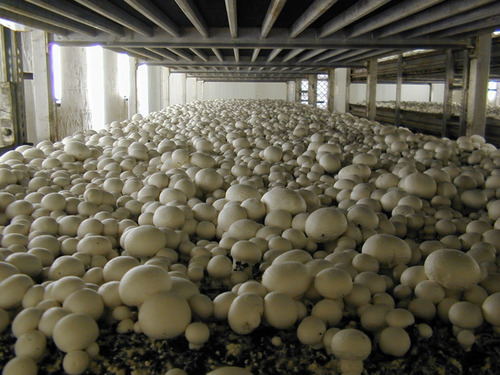

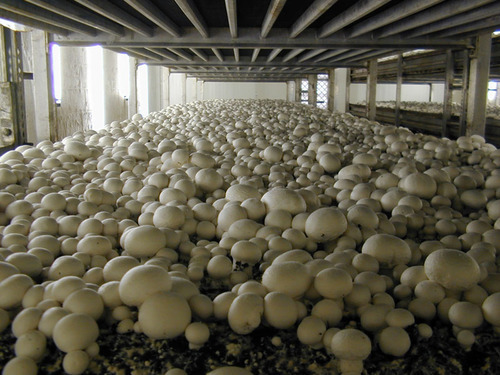

There are three sorts of Mushrooms that are being cultivated in India, they are button mushroom, straw mushroom and oyster mushroom. Paddy straw mushrooms can develop in temperatures ranging from 35⁰ to 40⁰C. Button mushrooms grow at some point in winter. Oyster mushrooms are grown in the northern plains. All the three mushrooms of business significance are grown with the aid of one of a kind techniques. They are grown on extraordinary beds called compost beds. Learn how to domesticate mushrooms of each type.

Steps of Mushroom Farming:

The six steps of mushroom farming are given as follows:

Step 1: Compost Preparation

To begin with this fabulous farming idea we need to delve right into the concept of “compost preparation”.

This initial step of compost preparation is generally done outdoors although an enclosed structure with a shade over it could be used. Here a concrete slab, also known as a wharf, is required for composting. Plus, a compost turner to aerate and irrigate the ingredients, and a trolley to move the ingredients to the turner is needed.

In earlier times piles were turned by hand using pitchforks, which is still an alternative to mechanical tools and equipment, but it is quite labour intensive and physically demanding for a job like this.

It is all initiated by mixing and wetting the required ingredients as they are stacked in a pile of rectangular shapes with tight sides and a loose centre. Normally, the bulk ingredients are put through a compost turner. After this water is sprinkled onto the horse manure or synthetic compost for instance, as these materials move past the turner. Now Nitrogen supplements and gypsum(CaSO4. 2H2O) are spread over the top of the bulk ingredients and are thoroughly and vigilantly mixed by the turner. Once the pile is soaked and formed, fermentation (composting) commences as a result of the exponential growth and reproduction of microorganisms, which is a natural process in the bulk ingredients.

This Compost for growing mushrooms develops as the chemical nature of the raw ingredients is converted by the activity of microorganisms, heat, and some exothermic chemical reactions. These things cumulatively result in a food source most suited for the growth of the mushroom and also inhibits the development of other fungi and bacteria. There must be optimal moisture, oxygen, nitrogen, and carbohydrates present throughout the process, otherwise, the process might stop. This is why water and other additives are added cyclically and periodically, and the compost pile is agitated as it moves through the turner.

Interestingly Gypsum here is added to minimize the viscosity the compost normally tends to have. Gypsum increases the fluidity of certain chemicals in the compost, and they adhere to straw or hay rather than hindering the porosity between the straws. Apart from this, the side benefit of this phenomenon is that air can permeate the pile comfortably, and the air is essential to the composting process. The exclusion of air results in an anaerobic environment in which putrid chemical compounds are formed which is extremely harmful to the crop. Gypsum is added at the outset of composting at approximately 18 kg per ton of dry ingredients.

Yet another important supplement is the Nitrogen supplements, which in general use today include brewer’s grain, seed meals of soybeans, peanuts, or cotton, and chicken manure, etc. The whole and sole purpose of these supplements are to increase the nitrogen content to 1.5 % for horse manure or 1.7 % for synthetic, both calculated on a dry weight basis. Synthetic compost requires the addition of ammonium nitrate or urea at the outset of composting to provide the compost microflora with a readily available form of nitrogen for their reproduction and growth.

But sometimes the Corn cobs are unavailable or available at a price considered to be exorbitant. Substitutes for corn cobs include shredded hardwood bark or sawdust, for instance, cottonseed hulls, neutralized grape pomace, cocoa bean hulls, and neutralized grape pomace. The management of a compost pile containing any one of these materials is unique in terms of what the requirements are for watering and the interval between turning the pile.

In the beginning, the compost pile should be 5 to 6 feet wide, 5 to 6 feet high, and lengthy by that. A two-sided box can be used to form the pile (rick), though some turners are equipped with a “ricker” so a box isn’t needed. The sides of the pile should be firm and dense, yet the centre must remain loose throughout Phase I composting. As the straw or hay softens during composting, the materials become less rigid and shrinkage can easily occur. If the materials become too compact, air cannot lurk around the pile and an airless environment would be developed.

This initial composting process lasts not more than a couple of weeks, depending on the nature of the material at the start and its characteristics at each point. There is a strong ammonia smell associated with composting, which is usually complemented by a sweet, mouldy smell. When compost temperatures are 68-degree centigrade and higher, and ammonia is present, chemical changes occur which result in a nourishing rather exclusively used by the mushrooms.

As a by-product of the chemical changes, heat is released and the compost temperatures increase. Temperatures in the compost can reach 76 to 82 degrees Celsius during the second and third turns when a desirable level of biological and chemical activities are happening. At the end of Phase one the compost should: 1) have a chocolatey brown colour; 2) have soft, tender straws, 3) have a moisture content of about 68 to 74 per cent; and 4) have a strong smell of ammonia. When the moisture, temperature, colour, and odour described have been achieved, congratulations! You’re now done with Step 1.

Hope you’ve enjoyed Phase I of Mushroom farming!

Step 2: Finishing the Compost

So, let’s just terminate the composting process altogether.

Now that you have terminated with phase one composting, we’ll be heading towards the second and extremely important step that is “Finishing the Compost”.

So, here are two major reasons for Phase two or step 2 of composting. Pasteurization is necessary to kill any unwanted bacteria, insects, nematodes, pests, fungi, or other headaches that may be present in the compost. And secondly, it is necessary to remove the ammonia which formed during Phase I composting. Ammonia at the end of Step 2 in a concentration higher than 0.07 per cent is often dangerous to mushroom spawn growth, so it must be eliminated; On average, a person can sense ammonia when the concentration reaches the threshold of 0.10 per cent.

Whether the compost is kept in beds, trays, or bulk, should be spread uniformly in-depth and compression or density. Compost density should allow for the gas to move around, this would make sure that ammonia and carbon dioxide would be replaced by the outside air.

Step 2 composting can be perceived as a regulated, temperature-dependent, ecological process using air to maintain the compost in a temperature range optimal for the de-ammonifying organisms to grow and reproduce. The growth of these thermophilic (heat-loving) organisms depends on the availability of usable carbohydrates and nitrogen, some of the nitrogen in the form of ammonia.

Optimum management for Phase II is difficult to pinpoint and most growers(commercial) tend toward one of the two systems in common use today: high temperature or low temperature. Due to the jargon nature of this process, it’s quite difficult to put the variables into exact numbers.

For that, you need to consult online, with someone who has experience in this field and it’s better if you find that person in your vicinity.

Step 3: Spawning

Mushroom spawning is similar to the seedling stage in agriculture and means keeping the spawn (mycelium) of mushrooms that can be purchased from a laboratory at nominal prices. After laying the spawns evenly on the tray and distributing it ergonomically, cover it with a thin layer of compost and keep it moist. Cover the tray with a wet sheet of paper and sprinkle water at regular intervals. The trays can be stacked on top of each other at a spacing of 15–20 cm. Keep the walls and floors wet to maintain a humidity-filled environment and temperature at 25 ° C.

Step 4: Casing

Be a bit vigilant about this one!

The casing is a covering applied to the spawn-run compost on which the mushrooms slowly and steadily form. The constituents are, field soil clay-loam, a mixture of peat moss with ground limestone, or reclaimed weathered, spent compost that could be utilised as the casing.

The Casing doesn’t require nutrients as the casing only acts as a water reservoir and a place where the formation of rhizomorphs takes place. The Rhizomorphs look like thick strings and form when the very fine mycelium fuses.

Casing must be pasteurized to eliminate any insects and pathogens which it might be carrying. It’s also quite important that the uniformity of the layers remains intact. This allows the spawn to move into and through the casing at the same pace and, ultimately, mushroom growth happens tauta chromatically. The casing should be able to retain moisture since moisture is essential for the development of a healthy mushroom.

The crop management after casing requires that the compost temperature be kept at around 24° C for up to 5 days after casing, and the relative humidity should be high. Thereafter, the compost temperature should be lowered to about -16.5°C each day until small mushroom initials have formed. Throughout the period following casing, water must be applied periodically to raise the moisture level to field capacity before the mushroom pins form. Knowing when, how, and how much water to apply to casing is an “art form” which is the subtle difference that acts as a trench between experienced growers from beginners.

Step 5: Pinning

The Mushroom instigates as and when rhizomorphs have started growing in the casing. The initials are minuscule but can be seen protruding on a rhizomorph. Once an initial grow four folds in size, the structure is a pin. Pins continue to grow larger through the button stage, and ultimately a button enlarges to a mushroom. The harvestable crop appears after around three weeks or maybe a few days here and there. Pins develop when the carbon dioxide content of room air is lowered to 0.08 per cent or lower, depending on the skill set of the grower, by introducing clean and fresh air into the growing room. Outside air has a CO² content of about 0.04 %.

If the CO² is lowered too early by airing too soon, the mycelium ceases to grow through the casing and mushroom initials plunge to the surface of the casing. As such mushrooms continue to thrive, they push through the casing and are tedious at harvest time. Too little wetness can also result in mushrooms forming below the surface of the casing. Pinning affects both the potential yield and quality of a crop and is a stepping stone in the production cycle.

Step 6: Cropping

It’s the final but a step of utmost importance. The value you’ll be generating out of this business always goes hand in hand with the ingenuity you’re putting in the cropping process.

It varies from person to person and depends upon the given below factors:

- Production Capacity

- Ambient Conditions

- Investment

- Cropping Pattern

These were some of the variables you have to take care of if you want good returns. This comes in naturally as you get more and more experienced in the trade.

Disease and pest controlling measures in Mushroom Farming:

Mushroom flies:

These flies are small, delicate, black, yellowish or sometimes brown with different types of wing venation and size.

Management:

Spring is inside the wall of the mushroom house.

The insecticide should be added in the last turning of the compost.

Mites:

They are small in size and are Majorly white, yellow, red and brown.

They can be found running over the surface of the fruit bodies, mushroom beds and on the floors and walls of the mushroom houses.

They damage the crop by feeding on the spawn to make holes in the mushroom caps and stalks and cause stunting of fruit bodies as well as brown spots on the caps and stems.

Management:

Proper pasteurization of compost.

Proper hygiene and sanitation.

Disinfection of the mushroom houses by spraying 0.1% dicofol.

Burning sulphur in the empty room.

Springtails:

They are silver-grey 2 brown colours with a light violet band along the sides of the body and black cellular fields present on the head.

They are the main species that damage mushrooms.

They enter mushroom houses along with organic matter.

They feed on mycelium from spawn.

They also feed on the gills of the oyster mushroom destroying the lining and spit out the mycelial strands at the base of the stripes.

They also attack the fruiting bodies of button mushrooms and cause slight pitting and browning at feeding sites.

Management:

Cleaning surrounding and inside of the mushroom house.

Proper disposal of spent compost.

Proper pasteurization of composed and casing material.

Raising the crop above the floor level.

Diseases:

Fungal diseases dry bubble: Verticillium fungicola

They are Muddy brown, often sunken spots on the cap of the mushrooms.

Greyish white mouldy

growth was seen on the pileus.

In a later stage, the mushroom

becomes dry and leathery.

Management:

Use clean equipment.

Control flies and mites.

Sanitary condition in growth house.

Bubbles can be destroyed with salt.

Infected mushrooms should be destroyed to prevent the spread.

Wet bubble:

Mycogen perniciosa:

Malformed mushrooms with swollen stipes.

Reduced or deformed caps.

Undifferentiated tissue becomes necrotic and a wet, soft rot emits a bad odour.

An amber liquid appears on infected mushrooms.

Mushrooms become brown.

Bubbles may be as large as a grapefruit.

It is also a parasite of wild mushrooms.

It produces two spore types, one which is small and water-dispersed like Verticillium. the second which is a large resting spore capable of persisting for a long time in the environment.

Management:

Hygiene and sanitation in a growth house.

Clean surrounding.

Benomyl at the rate of 0.95 g/m².

Carbendazim and Thiabendazole at the rate of 0.62 g/m².

Bacterial diseases:

Bacterial spot / brown blotch: Pseudomonas tolaasii

Pale yellow spots on the surface of the piles later turn yellow.

In severe cases, mushrooms are radially streaked.

Damage at storage and transit.

High humidity and watery conditions are favourable for disease.

Vector: Tyroglyphus mite.

Lesions on tissue that are pale yellow initially later become a golden yellow or rich chocolate brown.

The discolouration is superficial (not more than 2 to 3mm).

Management:

Hygiene and sanitation.

Low humidity.

Watering with an A1 50 ppm chlorine solution.

Viral diseases:

Virus (several)

Double-stranded RNA

Reduced cropping,

Bare patches on the beds,

Long-bent stalks with small caps,

Premature opening of mushrooms,

Stalks tapering towards the base of the stalk.

Management:

Farm hygiene.

Clean trays to prevent infection from old infected mycelia.

Maintaining 60°C temperature throughout the compost.

Advantages of Mushroom Farming:

- Use of ideal structure

- Environment friendly

- Use agriculture waste as substrate

- Possible production all the year-round

- Uses less capital

- Income and employment generator

- Mushrooms are rich in digestible essentials amino acids, rich protein, vitamins and minerals but low volume of high-quality unsaturated fat and water-soluble carbohydrates.

- Have high medicinal properties.

- It constitutes one of the most promising resources for promoting rapid socio-economic development.

Disadvantages of Mushroom Farming:

- Lack of availability of quality spawn.

- Mushroom spores can enter your lungs and cause serious health complications.

- Mushrooms have an extremely strong smell and it worsens over time.

- Need to constantly regulate the temperature.

- Lack of proper training.

- The chances of contamination are high in the Farming of Mushroom.

Conclusion:

The world mushroom industry has accelerated very rapidly in the last two decades by way of consisting of new types of mushrooms for commercial farming. However, mushroom as a vegetable has not located an ordinary area amongst Indian consumers. Despite a favourable agro-climate, an abundance of agricultural wastes, noticeably low-cost labour and wealthy fungal biodiversity, India has seen a lukewarm response in its growth. Currently, the whole mushroom manufacturing industry in India is around 0.13 million tonnes.

From 2010-2017, the mushroom industry in India has recorded a common increase charge of 4.3% per year. Of the total mushrooms produced, white button mushroom bills for 73%, observed through oyster mushroom (16%), paddy straw mushroom (7%) and milky mushroom (3%). Compared to other vegetables; The per capita consumption of mushrooms in India is low and information shows that it is much less than 100 grams per year.

In the 12 months 2016-2017, the Indian mushroom enterprise generated an income of Rs. 7282.26 lakhs by exporting 1054 quintals of white button mushroom in canned and frozen form. Considering the production figures, the demand for spawn in India is estimated to be around 8000-10000 tonnes per year. The majority of this business spawn is furnished to non-public producers and the contribution of public region corporations in spawn grants used to be constrained to only 10%. In this article, we attempted to analyse the contemporary state of affairs of the mushroom industry with the assistance of AICRP community centres placed throughout the US and discuss the possibilities and challenges for the improvement of mushroom entrepreneurship in India.

8 Responses

I want to open mushroom culture how can open mushroom culture please tell me

Mushroom farming is nicely described and is very educative for beginners.Alongwith the theoretical approach practical approach is required for perfection.Collection/selection/preparation of right type of spun and mushroom seeds are the main thing after proper bed preparation .This is very important for button mushroom farming.

Good job bro, very informative, high five for your blog. Keep blogging.

Pls write in hindi

Sir ham v karna chahte hai to kaise start kare

Sir this is tharunesh I am interested in moshroom foming but I don’t have money but I have foming lots of space in in my shed

Interested

I want to start mushroom business in my area.

I have our own land.

Kindly please give information and guide to us.

Regards,

Nagaraj Raikar

8660785647

WhatsApp:9986777824